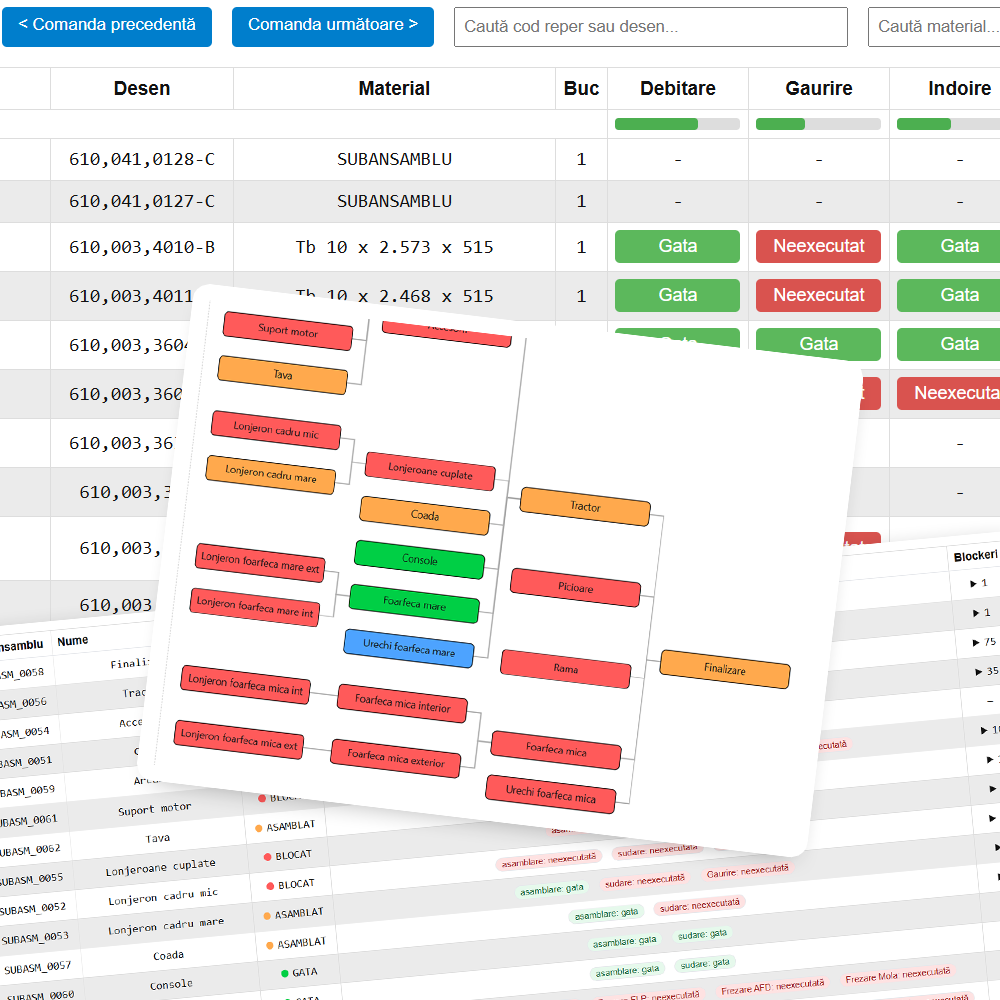

Track Your Order in Real-Time

Unlike traditional manufacturers, we give you complete transparency into every production stage

- Real-time production status tracking

- Operation-by-operation progress updates

- Subassembly visualization dashboard

- Complete quality traceability

- QR code integration for instant access

Coming Soon Optional client portal access